THERMOPLASTIC BEARINGS (WMG)

WMG® BEARINGS

Our WMG range of plastic bearings can be used across a wide range of applications and industries.

These thermoplastic bearings are suitable for applications requiring high abrasion resistance in atmospheres where dust or other particles are a constant problem. Our WMG range has a very low level of dynamic friction and almost zero stick-slip characteristics.

We can also offer bearings manufactured in many different types of plastic material to suit various applications and can be machined or moulded depending on the quantities required.

For fitting information, please refer to the Bearing Selector.

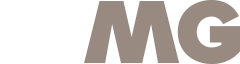

WMG® PLAIN BEARINGS

These thermoplastic bearings are suitable for applications requiring high abrasion resistance in atmospheres where dust or other particles are a constant problem. Our WMG range has a very low level of dynamic friction and almost zero stick slip characteristics.

Our WMG range of plain bearings are available in metric sizes only. Our in-house machining service is able to produce non-standard sizes to suit customer specific requirements.

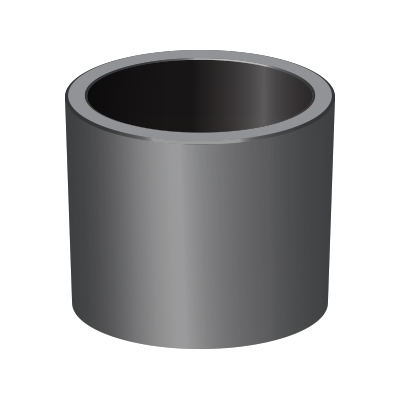

WMG® FLANGED BEARINGS

These thermoplastic bearings are suitable for applications requiring high abrasion resistance in atmospheres where dust or other particles are a constant problem. Our WMG range has a very low level of dynamic friction and almost zero stick slip characteristics.

Our WMG flanged bearings are available in metric sizes only. Our in-house machining service is able to produce non-standard sizes to suit customer specific requirements.

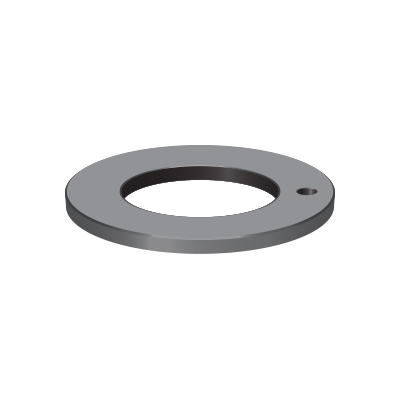

WMG® WASHERS

These thermoplastic bearings are suitable for applications requiring high abrasion resistance in atmospheres where dust or other particles are a constant problem. Our WMG range has a very low level of dynamic friction and almost zero stick slip characteristics.

The WMG washers are available in metric sizes only. Our in-house machining service is able to produce non-standard sizes to suit customer specific requirements.

Structure | PA66 nylon with fibres and PTFE |

PV (N/mm² x m/s) | 0.4 max | Static load (N/mm²) | 80 max |

Sliding speed (m/s) | 1.0 max | Intermittent temperature (°C) | -70 to 200 |

Operating temperature (°C) | -40 to 150 | Thermal Conductivity (W/mk) | 0.2 |

Coefficient of friction – Dry | 0.08 to 0.2 | Hardness (rockwell) (HRR) | 107 min |

Hardness (Shore D) | 80 min | Tensile strength (N/mm²) | 60 min |

Density (g/cm³) | 1.46 |

Compressive strength (N/mm²) | 100 min |

E-module (N/mm²) | 1500 min | Static pressure of surface at 20 degrees (N/mm²) | 100 min |