BOWMET

BOWMET – HEAVY DUTY BEARINGS FOR APPLICATIONS THAT OTHER BEARINGS CAN’T HANDLE!

The BowMet range has been billed as the biggest advance in plain bearings in more than 70 years by the industry press, and quite rightly so. This new range of heavy-duty bearings offers a higher load capacity than any other proprietary plain bearing. Its heat, speed and corrosion capabilities combine to offer a high strength bearing that can stand up to even the harshest of conditions.

These heavy-duty bearings have been developed using ToughMet® material by Materion in the USA. The ToughMet material that BowMet is made from was used on the Mars Rover in 2011, so that should give you some idea of just how ‘tough’ ToughMet is!

With a static load of 820 N/mm2 and an impressive PV factor of 9.6, these heavy-duty bearings are ideally suited to a wide range of harsh industrial applications including:

• Mining & quarrying

• Heavy construction

• Motorsport

• Offshore oil & gas

• Marine

The ToughMet material resists saltwater corrosion, hydrogen embrittlement and chloride stress-corrosion cracking better than most copper alloys. Indeed, in some sulphide environments, the corrosion rate is comparable to stainless steel and nickel alloys.

The capacity to deliver increased reliability, reduced downtime, lower maintenance costs and ultimately fewer warranty claims mean that BowMet range of heavy-duty bearings really is nothing short of a revolution in bearing design and capability.

BOWMET® HIGH LOAD STRIP BEARINGS

The BowMet range has been developed using ToughMet heavy duty spinodal bronze.

Our in-house machining service can produce non-standard sizes for specific customer requirements.

For an informal discussion about your specific application/project, feel free to give us a call on +44(0) 1235 462500 or on info@bowman.co.uk

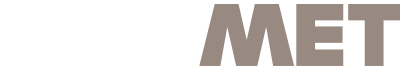

BOWMET® PLAIN BEARINGS

The BowMet range has been developed from ToughMet spinodal bronze and are suitable for a wide range of heavy duty applications.

In addition to smooth bores we are also able to offer BowMet plain bearings with thru-holes and diamond pockets as standard. We can also offer bespoke products with special grooves, oil-holes and various other features.

Our in-house machining service is also able to produce non-standard sizes to suit specific customer requirements.

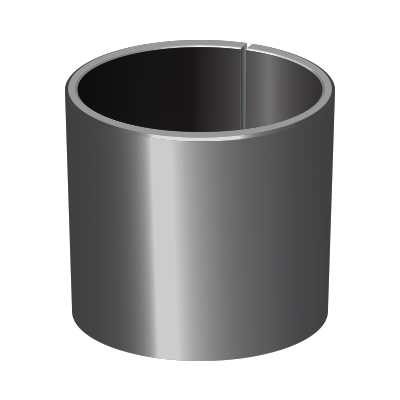

BOWMET® FLANGED BEARING

The BowMet range has been developed using ToughMet heavy duty spinodal bronze.

In addition to smooth bores, we are also able to offer BowMet flanged bearings with thru-holes.

Our in-house machining service can produce non-standard sizes for specific customer requirements.

BOWMET® WASHERS

Our range of BowMet Washers are made from ToughMet spinodal bronze and are suitable for a wide range of heavy duty applications.

For an informal discussion about your specific application/project, feel free to give us a call on +44(0) 1235 462500 or on info@bowman.co.uk

BOWMET® STRIPS

The BowMet range has been developed using ToughMet heavy duty spinodal bronze.

Our range of springs made from ToughMet® spinodal bronze is an innovative range that can replace high strength copper alloy springs and can be laser cut or wire eroded/stamped according to the quantity needed to suit customer requirements.

Structure | Toughmet ® spinodal bronze with optional lubrication holes/indentations |

Max PV – Dry (N/mm² x m/s) | 1.6 | Max PV – Oiled (N/mm² x m/s) | 9.6 |

Max Static load (N/mm²) | 820 | Max Dynamic load (N/mm²) | 340 |

Max Sliding speed – Dry (m/s) | 3 | Max Sliding speed – With Oil (m/s) | 10 |

Operating temperature (°C) | -250 to 300 |

Thermal Conductivity (W/mk) | 38 |

Coefficient of thermal expansion | 16.4 x 10-6/°C | Coefficient of friction – Dry | 0.25 |

Coefficient of friction – With Oil | 0.04 |

Recommended shaft finish (Ra) | 0.4 max (N5) |

Recommended shaft hardness (HRC) | 60 |

Hardness (HRC) | 30 min |

Ultimate Tensile strength (N/mm²) | 860 | Yield strength (N/mm²) | 725 |

Elongation (%) | 10 | Elastic modulus (N/mm²) | 144000 |