WRAPPED ACETAL LINED BEARINGS (WMX)

WMX® BEARINGS

Our WMX range of wrapped acetal lined bearings is suitable for rotary and oscillating movement applications. They benefit from long re-lubrication intervals, no absorption of water, outstanding damping behaviours and have a low susceptibility to edge loading.

The WMX range is ideal for the automotive, machine building and agricultural industries and indeed any application where lubricant cannot be supplied continuously.

Just a few examples of where our WMX range is used are as follows:

• Rear chassis hinges

• Articulation joints

• Spindles of drills

• Gearboxes & clutches

• Grinding and milling machines

STRUCTURE

• Our wrapped acetal lined bearings have a high wear resistance and low friction even with very small quantities of lubricant

• The surface carries a pattern of circular indents which should be filled with grease on assembly

• Low carbon steel gives exceptionally high load carrying capacity and excellent heat dissipation

• Our WMX range of wrapped acetal bearings can hugely reduce maintenance costs on projects large and small and are stocked in metric plain, imperial plain, metric washers. Imperial washers, metric strip and imperial strip.

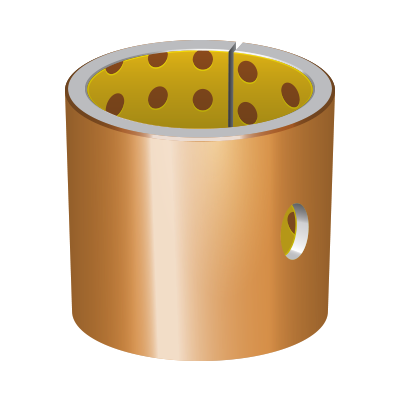

WMX® PLAIN BEARINGS

Our WMX range of wrapped acetal lined bearings are suitable for rotary and oscillating movement applications.

The WMX plain bearings are available in metric and imeprial sizes as standard. Our in-house machining service is able to offer non-standard sizes to suit customer specific requirements.

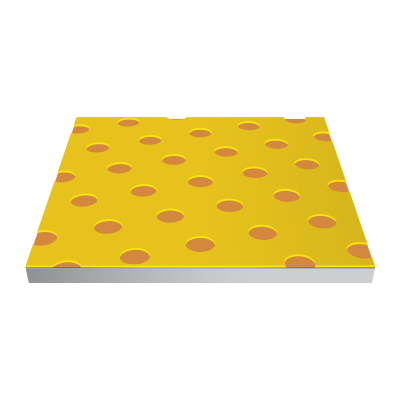

WMX® BEARING STRIP

Our WMX range of bearing strip is suitable for rotary and oscillating movement applications.

The WMX bearing strip is made from carbon steel with a sintered bronze layer and an acetal co-ploymer layer.

Our machining service is able to produce non-standard sizes to suit customer specific requirements.

Please contact us for information on sizes.

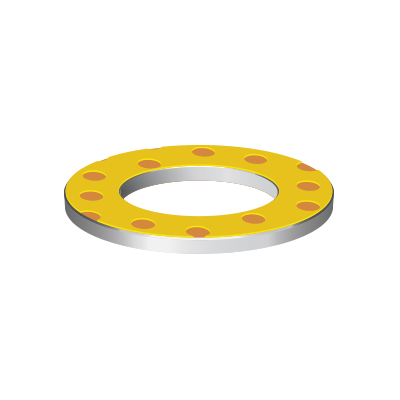

WMX® WASHERS

Our WMX range of wrapped acetal lined washers are suitable for rotary and oscillating movement applications.

The WMX washers are made from carbon steel and with a sintered bronze layer and an acetal co-ploymer layer.

Our machining service is able to produce non-standard sizes to suit customer specific requirements.

Structure | S.A.E. 1010 steel backing strip with sintered bronze and Acetal Copolymer layers |

Max PV – Dry (N/mm² x m/s) | 2.8 | Max Static load (N/mm²) | 140 |

Max Dynamic load (N/mm²) | 70 | Max Sliding speed – With Grease (m/s) | 2.5 |

Operating temperature (°C) | -40 to 110 | Thermal Conductivity (W/mk) | 2 |

Coefficient of friction – With Grease | 0.05 to 0.15 |

Recommended shaft hardness (HB) | 200 min |